Sassa da yawa nasabbin kayan rage kuzarikumagiyar motaaikin yana buƙatar a yi allurar feshi bayan niƙa gear, wanda zai lalata ingancin saman haƙori, har ma ya shafi aikin NVH na tsarin. Wannan takarda tana nazarin ƙaiƙayin saman haƙori na yanayin tsarin feshi daban-daban da sassa daban-daban kafin da bayan feshi. Sakamakon ya nuna cewa feshi zai ƙara ƙaiƙayin saman haƙori, wanda halayen sassa, sigogin tsarin feshi da sauran abubuwa ke shafarsa; A ƙarƙashin yanayin tsarin samar da rukuni na yanzu, matsakaicin ƙaiƙayin saman haƙori bayan feshi shine sau 3.1 fiye da kafin feshi. An tattauna tasirin ƙaiƙayin saman haƙori akan aikin NVH, kuma an gabatar da matakan inganta ƙaiƙayin bayan feshi.

A ƙarƙashin bayanan da ke sama, wannan takarda ta tattauna daga waɗannan fannoni uku:

Tasirin sigogin tsarin zubar da ciki na harbi akan rashin kyawun saman hakori;

Matakin ƙara girman harbin da ke fitowa a kan ƙaiƙayin saman haƙori a ƙarƙashin yanayin tsarin samar da tsari na yanzu;

Tasirin ƙaruwar ƙaiƙayin saman haƙori akan aikin NVH da kuma auna inganta ƙaiƙayin bayan an yi allurar fitsari.

Harbin peening yana nufin tsarin da ƙananan harsasai da yawa masu tauri da motsi mai sauri ke kaiwa saman sassa. A ƙarƙashin tasirin babban gudu na harbin, saman ɓangaren zai samar da ramuka kuma lalacewar filastik za ta faru. Ƙungiyoyin da ke kewaye da ramukan za su tsayayya da wannan nakasu kuma su haifar da damuwa mai ƙarfi. Rufe ramuka da yawa zai samar da wani Layer na damuwa mai ƙarfi iri ɗaya a saman ɓangaren, don haka inganta ƙarfin gajiya na ɓangaren. Dangane da hanyar samun babban gudu ta hanyar harbi, yawanci ana raba peening zuwa peening iska mai matsawa da peening centrifugal, kamar yadda aka nuna a Hoto na 1.

Fuskar iska mai matsewa tana ɗaukar iska mai matsewa a matsayin ƙarfi don fesa harbin daga bindiga; Fashewar harbin centrifugal tana amfani da injin don tuƙa impeller don juyawa a babban gudu don jefa harbin. Mahimman sigogin tsari na fuskar harbi sun haɗa da ƙarfin jikewa, rufewa da halayen matsakaici na fuskar harbi (abu, girma, siffa, tauri). Ƙarfin jikewa siga ce don siffanta ƙarfin fuskar harbi, wanda aka bayyana ta tsayin baka (watau matakin lanƙwasa na yanki gwajin Almen bayan fuskar harbi); Yawan rufewa yana nufin rabon yankin da ramin ya rufe bayan fuskar harbi zuwa jimlar yankin da aka fuskar harbi; Kayayyakin watsa shirye-shiryen harbi da aka fi amfani da su sun haɗa da harbin yanke waya na ƙarfe, harbin ƙarfe da aka yi da siminti, harbin yumbu, harbin gilashi, da sauransu. Girman, siffa da tauri na kafofin watsa shirye-shiryen fuskar harbi suna da matakai daban-daban. Ana nuna buƙatun tsari na gabaɗaya don sassan shaft na jigilar kaya a cikin Tebur 1.

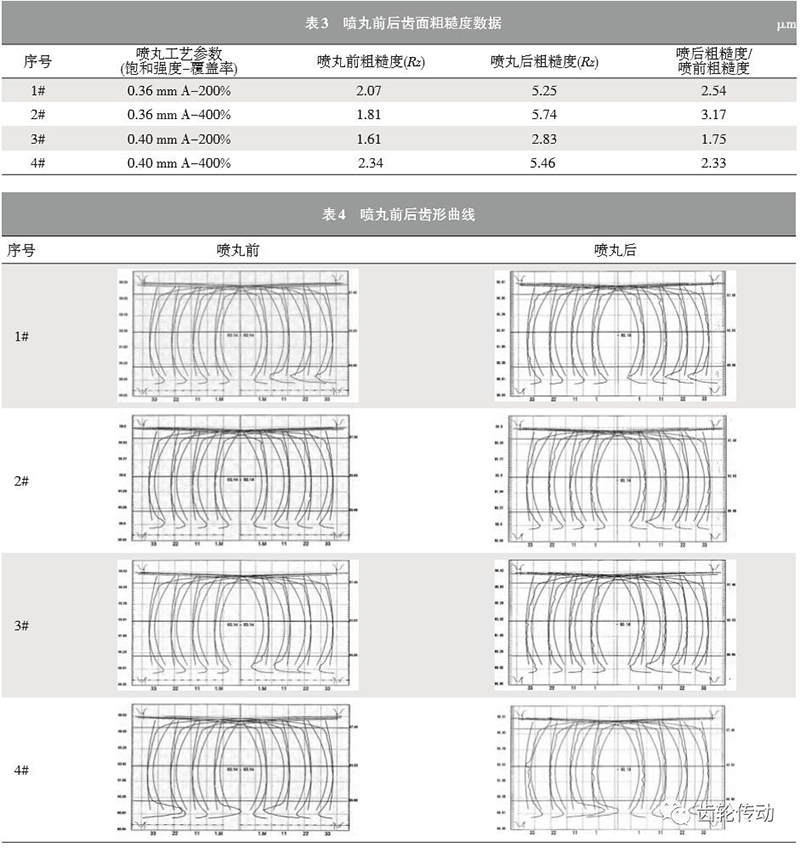

Sashen gwaji shine gear ɗin tsakiyar shaft 1/6 na aikin haɗin gwiwa. Tsarin gear ɗin an nuna shi a Hoto na 2. Bayan niƙa, ƙaramin tsarin saman haƙori shine Grade 2, taurin saman shine 710HV30, kuma zurfin Layer mai tauri mai inganci shine 0.65mm, duk a cikin buƙatun fasaha. An nuna taurin saman haƙori kafin a cire harsashi a cikin Jadawali na 3, kuma an nuna daidaiton bayanin haƙori a Jadawali na 4. Ana iya ganin cewa taurin saman haƙori kafin a cire harsashi yana da kyau, kuma lanƙwasa bayanin haƙori yana da santsi.

Tsarin gwaji da sigogin gwaji

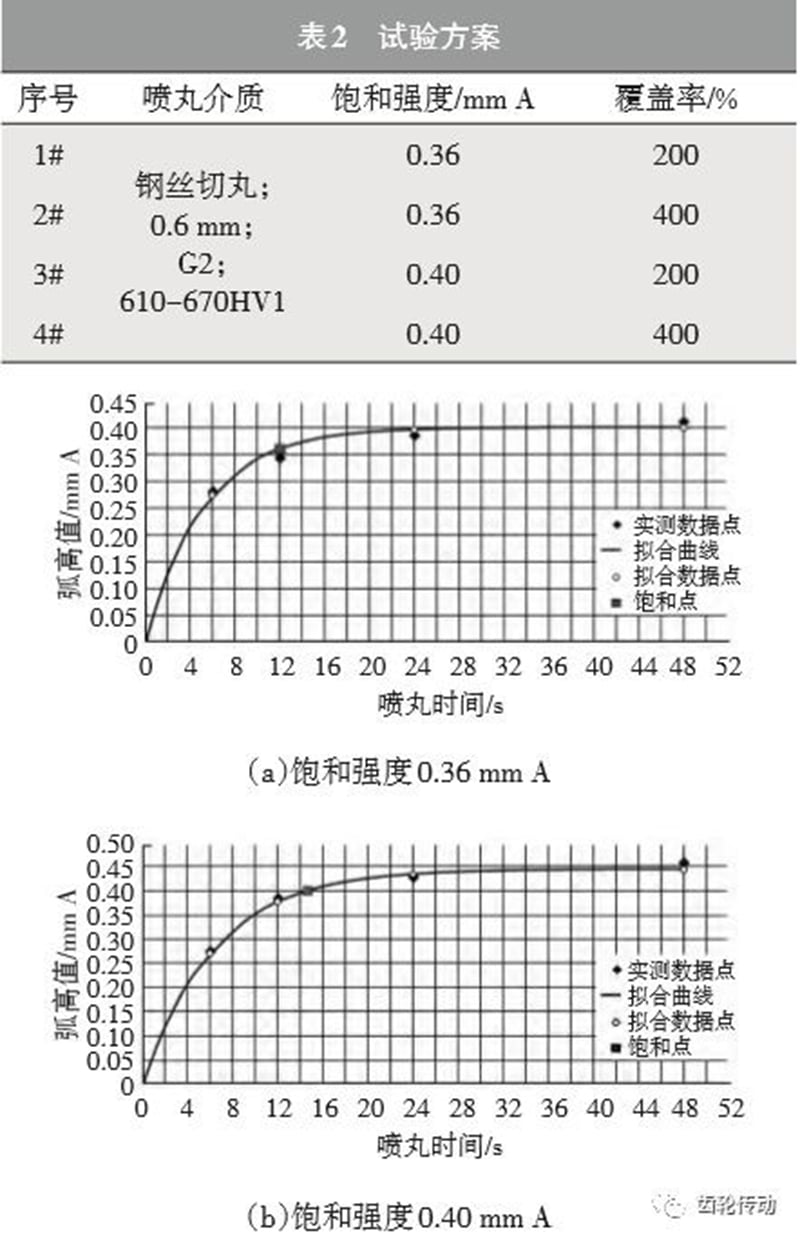

Ana amfani da injin fesa iska mai matsewa a gwajin. Saboda yanayin gwajin, ba zai yiwu a tabbatar da tasirin matsakaicin halayen fesawa na harbi ba (abu, girma, tauri). Saboda haka, halayen famfon fesawa na harbi suna nan a cikin gwajin. Tasirin ƙarfin jikewa da rufewa kawai akan ƙaiƙayin saman haƙori bayan fesawa na harbi ne aka tabbatar. Duba Jadawali na 2 don tsarin gwajin. Tsarin tantance takamaiman sigogin gwaji kamar haka: zana lanƙwasa mai jikewa (Hoto na 3) ta hanyar gwajin fom ɗin Almen don tantance wurin jikewa, don kulle matsin iska mai matsewa, kwararar harbin ƙarfe, saurin motsi na bututun fesawa, nisan bututun fesawa daga sassa da sauran sigogin kayan aiki.

sakamakon gwaji

An nuna bayanan rashin lafiyar saman haƙori bayan an yi allurar a cikin Jadawali na 3, kuma an nuna daidaiton yanayin haƙori a Jadawali na 4. Ana iya ganin cewa a ƙarƙashin yanayin rashin lafiyar harbi guda huɗu, rashin lafiyar saman haƙori yana ƙaruwa kuma lanƙwasa na yanayin haƙori ya zama mai lanƙwasa da lanƙwasa bayan an yi allurar a cikin jijiya. Ana amfani da rabon rashin lafiyar bayan an yi allurar a cikin jijiya kafin a yi allurar a matsayin siffanta girman rashin lafiyar (Jadawali na 3). Ana iya ganin cewa girman rashin lafiyar ya bambanta a ƙarƙashin sharuɗɗan tsari guda huɗu.

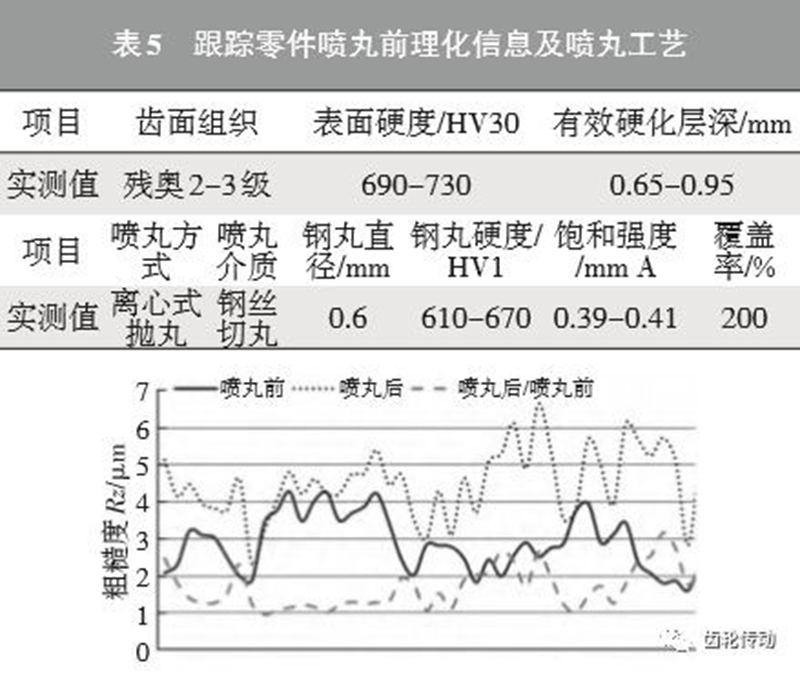

Bin diddigin Girman Taurin saman Hakori ta hanyar harbin Peening

Sakamakon gwajin da aka yi a Sashe na 3 ya nuna cewa ƙaiƙayin saman haƙori yana ƙaruwa a matakai daban-daban bayan an yi allurar fitsari tare da hanyoyi daban-daban. Domin fahimtar ƙara girman ƙaiƙayin a kan ƙaiƙayin saman haƙori da kuma ƙara yawan samfuran, an zaɓi abubuwa 5, nau'ikan 5 da sassa 44 gaba ɗaya don bin diddigin ƙaiƙayin kafin da bayan an yi allurar fitsari a ƙarƙashin yanayin tsarin samar da allurar fitsari. Duba Jadawali na 5 don bayanan jiki da sinadarai da kuma bayanan tsarin buɗewar harbi na sassan da aka bi diddigin bayan niƙa kayan aiki. Bayanan ƙaiƙayi da girma na saman haƙori na gaba da na baya kafin a yi allurar fitsari an nuna su a Hoto na 4. Hoto na 4 ya nuna cewa kewayon ƙaiƙayin saman haƙori kafin a yi allurar fitsari shine Rz1.6 μ m-Rz4.3 μ m; Bayan buɗewar harbi, ƙaiƙayin yana ƙaruwa, kuma kewayon rarrabawa shine Rz2.3 μ m-Rz6.7 μ m; Matsakaicin ƙaiƙayin ana iya ƙarawa zuwa sau 3.1 kafin a yi allurar fitsari.

Abubuwan da ke haifar da rashin kyawun fuskar haƙori bayan an yi masa allurar fitsari

Za a iya gani daga ƙa'idar buɗe ido ta hanyar harbi cewa babban tauri da kuma saurin harbi mai sauri suna barin ramuka marasa adadi a saman ɓangaren, wanda shine tushen matsin lamba na matsewa. A lokaci guda, waɗannan ramukan za su ƙara ƙaiƙayin saman. Halayen sassan kafin buɗe ido da sigogin tsarin buɗe ido ta hanyar harbi za su shafi ƙaiƙayin bayan buɗe ido ta hanyar harbi, kamar yadda aka jera a cikin Jadawali na 6. A cikin Sashe na 3 na wannan takarda, a ƙarƙashin yanayi huɗu na tsari, ƙaiƙayin saman hakori bayan buɗe ido ta hanyar harbi yana ƙaruwa zuwa matakai daban-daban. A cikin wannan gwajin, akwai masu canji guda biyu, wato, ƙaiƙayin kafin harbi da sigogin tsari (ƙarfin cikawa ko rufewa), waɗanda ba za su iya tantance alaƙar da ke tsakanin ƙaiƙayin bayan harbi da kowane abu mai tasiri ba. A halin yanzu, masana da yawa sun yi bincike kan wannan, kuma sun gabatar da samfurin hasashen ka'ida na ƙaiƙayin saman bayan buɗe ido ta hanyar kwaikwayon abubuwa masu iyaka, wanda ake amfani da shi don annabta ƙimar ƙaiƙayin daban-daban na hanyoyin buɗe ido ta hanyar harbi.

Dangane da ainihin gogewa da binciken wasu masana, ana iya hasashen yanayin tasirin abubuwa daban-daban kamar yadda aka nuna a cikin Jadawali na 6. Ana iya ganin cewa rashin ƙarfi bayan harbi yana shafar abubuwa da yawa gaba ɗaya, waɗanda kuma su ne manyan abubuwan da ke shafar matsin lamba na matsi. Domin rage rashin ƙarfi bayan harbi ya buɗe bisa ga manufar tabbatar da matsin lamba na matsi, ana buƙatar gwaje-gwaje masu yawa na tsari don ci gaba da inganta haɗin sigogi.

Tasirin ƙaiƙayin saman haƙori akan aikin NVH na tsarin

Sassan gear suna cikin tsarin watsawa mai ƙarfi, kuma ƙaiƙayin saman haƙori zai shafi aikin NVH ɗinsu. Sakamakon gwaji ya nuna cewa a ƙarƙashin kaya da saurin iri ɗaya, girman ƙaiƙayin saman, girman girgiza da hayaniyar tsarin; Lokacin da kaya da saurin suka ƙaru, girgiza da hayaniyar suna ƙaruwa a bayyane.

A cikin 'yan shekarun nan, ayyukan sabbin na'urorin rage kuzari sun karu da sauri, kuma suna nuna yanayin ci gaban babban gudu da babban karfin juyi. A halin yanzu, matsakaicin karfin juyi na sabon na'urar rage kuzarinmu shine 354N · m, kuma matsakaicin gudun shine 16000r/min, wanda za a kara zuwa sama da 20000r/min a nan gaba. A karkashin irin wannan yanayin aiki, dole ne a yi la'akari da tasirin karuwar karfin juyi na saman haƙori akan aikin NVH na tsarin.

Matakan ingantawa don ƙaiƙayin saman haƙori bayan an yi masa allurar fitsari

Tsarin cire haƙori bayan niƙa gear zai iya inganta ƙarfin gajiyar hulɗar haƙorin gear da ƙarfin lanƙwasa na tushen haƙori. Idan dole ne a yi amfani da wannan tsari saboda dalilai masu ƙarfi a cikin tsarin ƙirar gear, domin la'akari da aikin NVH na tsarin, za a iya inganta ƙaiƙayin saman haƙorin gear bayan cire haƙori daga ɓangarorin da ke ƙasa:

a. Inganta sigogin tsarin cire haƙori, da kuma sarrafa faɗaɗa ƙaiƙayin saman haƙori bayan an cire haƙori bisa ga manufar tabbatar da matsin lamba da ya rage. Wannan yana buƙatar gwaje-gwaje da yawa na tsari, kuma bambancin tsarin ba shi da ƙarfi.

b. Ana amfani da tsarin haɗakar allurar ...

c. Bayan an yi allurar fitsari, ana ƙara wasu hanyoyin kamar goge haƙori da kuma yin wanki kyauta.

A cikin wannan takarda, an yi nazarin ƙaiƙayin saman haƙori na yanayin yanayin fitsari daban-daban da sassa daban-daban kafin da bayan fitsarin, kuma an yanke waɗannan ƙarshe bisa ga wallafe-wallafe:

◆ Yin fitsari a kan haƙori zai ƙara ƙaiƙayin saman haƙori, wanda halayen sassan kafin a yi fitsari a kan haƙori, sigogin tsarin fitsari a kan haƙori da sauran abubuwa ke shafarsa, kuma waɗannan abubuwan su ne muhimman abubuwan da ke shafar matsin lamba da ya rage;

◆ A ƙarƙashin yanayin samar da tsari na yanzu, matsakaicin ƙaiƙayin saman haƙori bayan yin fitsari sau 3.1 fiye da kafin yin fitsari;

◆ Ƙarar ƙaiƙayin saman haƙori zai ƙara girgiza da hayaniyar tsarin. Girman ƙarfin juyi da gudu, haka ƙarar girgiza da hayaniya ke bayyana;

◆ Za a iya inganta ƙaiƙayin saman haƙori bayan an yi allurar feshi ta hanyar inganta sigogin tsarin feshi, feshi mai haɗaka, ƙara gogewa ko kuma yin kyau bayan an yi allurar feshi, da sauransu. Ana sa ran inganta sigogin tsarin feshi zai sarrafa ƙara girman feshi zuwa kusan sau 1.5.

Lokacin Saƙo: Nuwamba-04-2022